IPT’s innovative solution for its sustainable business vision, is to integrate Technologies, Modern design and Responsive management relying on decades of experience to fulfill the needs of our international customers around the globe.

IPT offers a comprehensive portfolio and services of breakthrough technologies developed for the maximum benefit of the customers.

We are committed to constantly invest in research and experimental tests dedicated to develop and commercialize novel technologies and process improvements in collaboration with Research institutes, Universities, and Suppliers.

We develop original industrial processes for producing innovative products such as intermediates, building blocks, polymers and the innovative realization of high performance catalyst as strategically keys in the world wide market.

Licensing operates under specific conditions outlined in the contractual agreement. These conditions could include considerations on the geographical area of utilization of IPT’s intellectual properties, the duration of the license, and the specific purposes for which the intellectual properties can be employed.

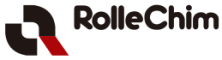

PDP (Process Design Package) is a package of Process oriented design and documents of the plant that elaborates process features of the technologies.BEDP (Basic Engineering Design Package) are provided based on our PDPs.

By engaging in partnerships with reputable manufacturers, the IPT ensures access to cutting- edge and specialized equipment designed for our specific processes. These key equipment items are often integral to the successful implementation of the IPT’s process technologies.

Technological Services that we are available to provide are related to the activities during project life cycle: early stages, project initiation, project management and supervision, training, R&D market application, troubleshooting and upgrading.

Technologies Portfolio

Value chain of IPT technologies focuses on the emerging processes that have high competitive advantages and market values for the customers.

Our ENB process technology is based on deep studies, pilot trials and precise engineering to offer it as captive use along with its EP(D)M technology.

Our ep(d)m solution technology and patents rely on our deep knowledge and skills in design, process control, operation and modern equipment which optimize the product quality, production cost, and environmental measures.

Propylene oxide is known as one of the most important intermediate chemicals for producing many chemical products like propylene glycols, polypropylene glycols, polyurethane, and many other specialty chemicals.

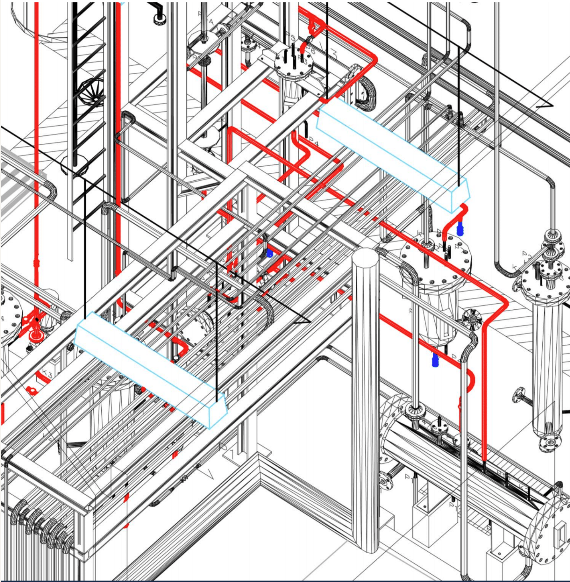

IPA process offered by IPT produces isopropanol via direct hydration of propylene on resin catalyst.

Ma process offered by IPT is a gas – phase catalytic reaction in a fixed bed reactor, that produce different ranges of Mono- , Di- and Tr- methylamine by precise control of operating parameters and ammonia(n) /methanol(c) ratio.

Our technology uses corotating twin-screw extruders for the devulcanization of FKM and HNBR production scraps.

Our technology uses Li-alkyls initiated anionic polymerization in aliphatic or cycloaliphatic solvent solution in batch reactors, suitable for obtaining block structures characterized by the absence of any tapered junction.

sSBR technology uses Li-alkyls initiated anionic polymerization in aliphatic or cycloaliphatic solvent solution in a cascade of CSTR reactors.

sSBR technology uses Li-alkyls initiated anionic polymerization in aliphatic or cycloaliphatic solvent solution in the presence of chelating ethers necessary to promote efficiently both the vinyl unit formation and a random distribution of styrene units along the polymer chain.

SEBS technology involves the use of a catalytic system based on titanium complex and an alkyl metal prepared directly inside the hydrogenation reactor (in situ technology) for the complete hydrogenation of the diene part of a SBS having a predefined macro and microstructure.

Nd-BR technology (High-cis polybutadiene) uses catalytic systems with precise Nd:Al:H2O:RCOOH ratios and purified fluids to obtain polymers with molecular weight distribution (MWD) with polydispersity index (Mw/Mn) lower than 2.7 and self-production of the pre-catalyst (prepared off-line) constituted by Nd-carboxylate.

Hydrogen Peroxide (HP) technology is based on anthraquinone method (AQ) that is used as the process carrier. HP is mainly used as captive unit in IPT technologies such as HPPO and Caprolactam Chain, while it has wide application in several industries.

sSBR technology uses Li-alkyls initiated anionic polymerization in aliphatic or cycloaliphatic solvent solution in a cascade of CSTR reactors.

Nd-BR technology (High-cis polybutadiene) uses catalytic systems with precise Nd:Al:H2O:RCOOH ratios and purified fluids to obtain polymers with molecular weight distribution (MWD) with polydispersity index (Mw/Mn) lower than 2.7 and self-production of the pre-catalyst (prepared off-line) constituted by Nd-carboxylate.

Coming Soon...

Nd-BR technology (High-cis polybutadiene) uses catalytic systems with precise Nd:Al:H2O:RCOOH ratios and purified fluids to obtain polymers with molecular weight distribution (MWD) with polydispersity index (Mw/Mn) lower than 2.7 and self-production of the pre-catalyst (prepared off-line) constituted by Nd-carboxylate.

Coming Soon...

sSBR technology uses Li-alkyls initiated anionic polymerization in aliphatic or cycloaliphatic solvent solution in a cascade of CSTR reactors.

Coming Soon...

Nd-BR technology (High-cis polybutadiene) uses catalytic systems with precise Nd:Al:H2O:RCOOH ratios and purified fluids to obtain polymers with molecular weight distribution (MWD) with polydispersity index (Mw/Mn) lower than 2.7 and self-production of the pre-catalyst (prepared off-line) constituted by Nd-carboxylate.

Coming Soon...

Nd-BR technology (High-cis polybutadiene) uses catalytic systems with precise Nd:Al:H2O:RCOOH ratios and purified fluids to obtain polymers with molecular weight distribution (MWD) with polydispersity index (Mw/Mn) lower than 2.7 and self-production of the pre-catalyst (prepared off-line) constituted by Nd-carboxylate.

Coming Soon...

Nd-BR technology (High-cis polybutadiene) uses catalytic systems with precise Nd:Al:H2O:RCOOH ratios and purified fluids to obtain polymers with molecular weight distribution (MWD) with polydispersity index (Mw/Mn) lower than 2.7 and self-production of the pre-catalyst (prepared off-line) constituted by Nd-carboxylate.

Our ENB process technology is based on deep studies, pilot trials and precise engineering to offer it as captive use along with its EP(D)M technology.

Our ep(d)m solution technology and patents rely on our deep knowledge and skills in design, process control, operation and modern equipment which optimize the product quality, production cost, and environmental measures.

Propylene oxide is known as one of the most important intermediate chemicals for producing many chemical products like propylene glycols, polypropylene glycols, polyurethane, and many other specialty chemicals.

IPA process offered by IPT produces isopropanol via direct hydration of propylene on resin catalyst.

Ma process offered by IPT is a gas - phase catalytic reaction in a fixed bed reactor, that produce different ranges of Mono- , Di- and Tr- methylamine by precise control of operating parameters and ammonia(n) /methanol(c) ratio.

Ma process offered by IPT is a gas - phase catalytic reaction in a fixed bed reactor, that produce different ranges of Mono- , Di- and Tr- methylamine by precise control of operating parameters and ammonia(n) /methanol(c) ratio.

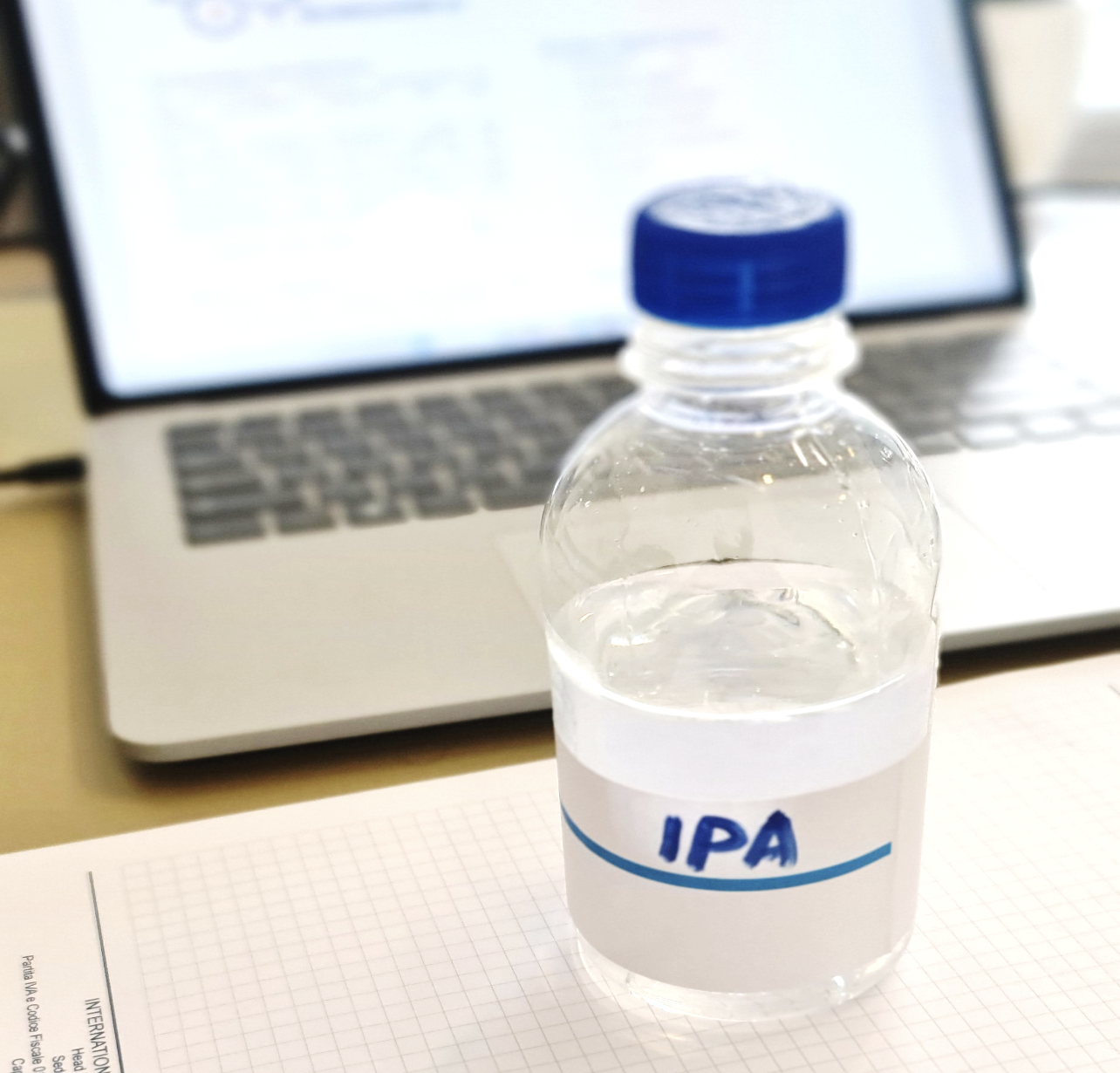

International presence

IPT quality and excellence in providing technological solutions are recognized internationally.

We are proud that our advanced processes are present around the globe through cooperation with reputable clients.

Some of our trusted partners