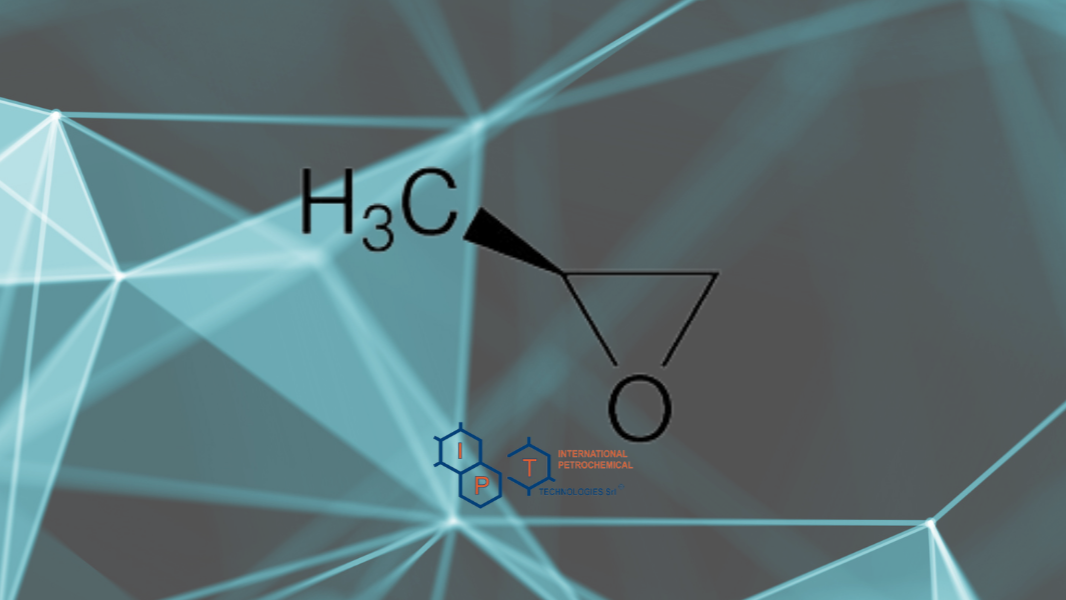

IPT Srl’s HPPO process for the production of Propylene Oxide (PO) is developed based on a slurry-phase reaction in a Continuous Stirred Tank Reactor (CSTR).

This technology stands out from conventional HPPO (Hydrogen Peroxide to Propylene Oxide) processes that typically rely on fixed-bed reactors. Our approach not only optimizes performance but also reduces operational and capital costs, offering a compelling alternative for PO production facilities worldwide.

🔹 Higher Yields — More Product, Less Waste Our process consistently achieves an overall PO yield of around 94%, compared to ~92% in typical fixed-bed HPPO systems. That’s not just a percentage point — it’s a measurable gain in efficiency and profitability

🔹 Better Heat Control = Safer, More Stable Operation Thanks to the natural mixing in a slurry reactor, heat is evenly distributed throughout the system. That means no hotspots, uniform temperature profile, better control of exothermic reaction, and more consistent product quality.

🔹 Stronger Reactivity and Faster Reactions In a fixed bed, the reactants have to find their way through a dense catalyst structure. In our slurry setup, everything is already well mixed in a homogeneous mode. The result? Faster reactions, better mass transfer and contact, and higher selectivity.

🔹 Lower Capital Cost The IPT slurry technology uses standard equipment, even in the reaction section. This means a lower capital investment compared to fixed-bed systems that require custom high-pressure tubular reactors. That’s a major plus for companies looking to scale quickly or build flexibly.

🔹 More Flexibility in Production Our process is more adaptable to varying production capacities, and different capacities can be designed by modular expansion strategies.

🔹 Ease of Maintenance Our slurry system with external filtration offer better accessibility for catalyst recovery, replacement, and filtration maintenance, unlike fixed-bed reactors where shutdowns is very complex and costly.

Why It Matters

The chemical industry is moving fast. With increasing pressure to cut costs, reduce environmental impact, and stay competitive, every percentage point counts.

At IPT Srl, we’re proud to offer a technology that’s:

· Efficient

· Cost-effective

· Environmentally smarter

· And most importantly, ready for the next generation of PO production.

If you’re considering a new PO plant or upgrading existing capacity, contact IPT Srl to learn how our innovation can benefit your project.

Stay tuned for further updates!